The global demand for electric multi-functional air fryers continues to surge, driven by preferences for healthier cooking and compact, efficient appliances. Ningbo Wasser Tek leads the charge in meeting this demand. With six state-of-the-art production lines and a 95% on-time delivery rate, the company ensures high-volume manufacturing with exceptional quality. Their advanced facilities, capable of producing innovative products like the Electric Dual Pot Air Fryer Digital and the Electric Double Air Fryer, represent a commitment to scalability and customer satisfaction. Additionally, their range includes the Air Fryer With Two Double and the Household Touch Screen Smart Air Fryers, catering to diverse consumer needs.

Key Features of Electric Multi-Functional Air Fryers

Versatile Cooking Functions

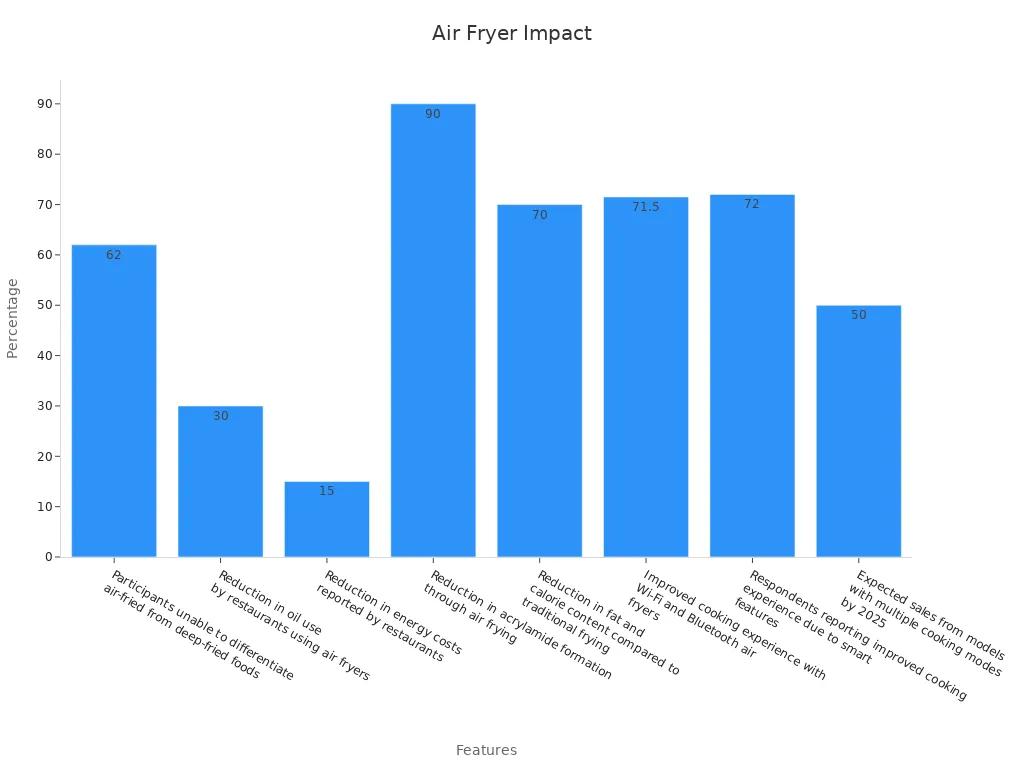

Electric multi-functional air fryers offer a wide range of cooking options, making them indispensable in modern kitchens. These appliances can fry, bake, roast, and grill, all while using significantly less oil compared to traditional methods. This versatility allows users to prepare healthier meals without compromising on taste. For instance, 62% of participants in a recent study could not differentiate between air-fried and deep-fried foods, showcasing the effectiveness of air fryers in delivering delicious results. Additionally, restaurants using air fryers reported a 30% reduction in oil usage, highlighting their efficiency in commercial settings.

Advanced Safety and User-Friendly Features

Safety and ease of use are critical in any kitchen appliance, and electric multi-functional air fryers excel in both areas. Features like auto shut-off, cool-touch handles, and non-slip bases ensure safe operation, even for beginners. User-friendly interfaces, including touch screens and pre-programmed settings, simplify the cooking process. Smart models equipped with Wi-Fi and Bluetooth connectivity enhance the cooking experience, with 72% of respondents reporting improved satisfaction due to these features.

Innovations like Electric Dual Pot Air Fryer Digital

Innovative designs, such as the Electric Dual Pot Air Fryer Digital, are transforming the way people cook. This model allows users to prepare two dishes simultaneously, saving time and energy. Its digital interface provides precise temperature and time controls, ensuring consistent results. By reducing fat and calorie content by up to 70%, these air fryers promote healthier eating habits. The chart below illustrates the impact of various features on consumer satisfaction, emphasizing the growing demand for models like the Electric Dual Pot Air Fryer Digital.

Six Production Lines for High-Volume Manufacturing

Layout and Workflow Optimization

Efficient layout and workflow optimization play a pivotal role in high-volume manufacturing. Ningbo Wasser Tek employs advanced facility planning techniques to ensure seamless material flow and reduce production bottlenecks. By strategically organizing equipment and workstations, the company minimizes idle time and enhances labor efficiency.

A well-designed layout not only improves productivity but also reduces operational costs. For instance, systematic layout planning can lower material handling expenses by up to 30%. The table below highlights the benefits of effective facility planning and layout redesign:

| Evidence | Description |

|---|---|

| Cost Reduction | Effective facility planning can reduce manufacturing costs significantly. |

| Performance Metrics | Analysis of layout design can improve production line performance. |

| Optimization Techniques | Heuristic methods like Tabu Search optimize facility design. |

By adopting these practices, Ningbo Wasser Tek ensures that its six production lines operate at peak efficiency, meeting the growing demand for products like the Electric Dual Pot Air Fryer Digital.

Scalability for Large Orders

Scalability is a critical factor in meeting large orders without compromising quality or delivery timelines. Ningbo Wasser Tek’s six production lines are designed to handle varying order sizes, from small batches to bulk manufacturing. This flexibility allows the company to cater to diverse client needs while maintaining consistent product quality.

The production lines are equipped with modular systems that can be adjusted to accommodate increased demand. For example, during peak seasons, the company can scale up operations to produce more units of popular models like the Electric Dual Pot Air Fryer Digital. This adaptability ensures that customers receive their orders on time, regardless of volume.

Automation and Technology Integration

Automation and technology integration are at the heart of Ningbo Wasser Tek’s manufacturing process. The company leverages cutting-edge machinery and software to streamline operations and enhance product quality. Automated systems reduce human error, ensuring consistent results across all production lines.

Advanced technologies like IoT-enabled devices and AI-driven analytics provide real-time insights into production metrics. These tools help identify inefficiencies and implement corrective measures promptly. For instance, automated quality control systems ensure that every Electric Dual Pot Air Fryer Digital meets stringent standards before leaving the factory.

By combining automation with skilled labor, Ningbo Wasser Tek achieves a perfect balance of efficiency and craftsmanship. This approach not only boosts productivity but also reinforces the company’s commitment to delivering high-quality products to its global clientele.

Benefits of Six Production Lines

Faster Production and Cost Efficiency

Ningbo Wasser Tek’s six production lines significantly enhance production speed while reducing costs. Each line operates with optimized workflows and advanced automation, enabling the company to produce large quantities of electric multi-functional air fryers in record time. This efficiency minimizes labor costs and material waste, translating into competitive pricing for customers.

Tip: Faster production cycles not only meet tight deadlines but also allow manufacturers to respond quickly to market trends.

The integration of modular systems further boosts production speed. These systems enable seamless transitions between product models, reducing downtime during retooling. For instance, during peak demand periods, the production lines can shift focus to high-demand models like the Electric Dual Pot Air Fryer Digital without compromising efficiency. This adaptability ensures that customers receive their orders promptly, even during seasonal surges.

Consistent Quality Across Products

Maintaining consistent quality across all products is a cornerstone of Ningbo Wasser Tek’s manufacturing process. The company employs rigorous quality control measures at every stage of production.

- Automation: Advanced technology ensures uniformity in assembly and reduces human error.

- Raw Material Inspection: All materials undergo thorough checks to meet strict specifications.

- In-Process Checks: Regular inspections during production identify and address issues early.

- Final Product Testing: Each air fryer is tested for functionality, safety, and durability before packaging.

- Certifications: Compliance with ISO 9001, CE, and RoHS standards guarantees quality, safety, and environmental responsibility.

These measures ensure that every product, from the Electric Double Air Fryer to the Household Touch Screen Smart Air Fryer, meets the same high standards. Real-time adjustments during production further enhance consistency, allowing the company to maintain its reputation for excellence.

Meeting Bulk Orders with Customization Options

The scalability of Ningbo Wasser Tek’s six production lines enables the company to handle bulk orders while offering customization options. Clients can request tailored features, such as unique color schemes, branding elements, or additional functionalities, without affecting delivery timelines.

Note: Customization options provide businesses with a competitive edge by aligning products with specific market demands.

The production lines’ modular design supports these customizations by allowing quick adjustments to machinery and processes. For example, a client requiring a batch of air fryers with dual cooking zones and a specific logo can rely on Ningbo Wasser Tek to deliver the order efficiently. This flexibility makes the company a preferred partner for businesses seeking high-quality, personalized appliances at scale.

By combining speed, quality, and adaptability, Ningbo Wasser Tek’s six production lines set a benchmark in the manufacturing of electric multi-functional air fryers.

Ningbo Wasser Tek’s six production lines demonstrate the power of efficiency, scalability, and quality in manufacturing. These advanced systems ensure faster production, consistent quality, and customization options. Manufacturers worldwide should embrace innovative production methods to meet growing demand. Adopting such strategies fosters sustainable growth and positions businesses for long-term success in competitive markets.

FAQ

What makes Ningbo Wasser Tek’s production lines unique?

Ningbo Wasser Tek uses modular systems, automation, and optimized workflows to ensure efficient, scalable, and high-quality manufacturing of electric multi-functional air fryers.

Can Ningbo Wasser Tek handle customized bulk orders?

Yes, their six production lines support customization, including branding, color schemes, and features, while maintaining consistent quality and timely delivery.

How does automation improve product quality?

Automation minimizes human error, ensures uniform assembly, and integrates real-time quality control systems, guaranteeing every product meets stringent standards.

Tip: Automation also accelerates production cycles, reducing costs and enhancing efficiency.

Post time: May-22-2025